We know that even a grain of dust or tiny droplet can damage a tough metal surface if the particle gathers up a high-enough speed when it smashes into it.

But until now there's been a problem figuring out how or why that damage happens. That's because the speed has to be really freaking high, and the scales are really incredibly tiny.

Now researchers from MIT have developed cameras that are fast enough, and have enough magnification, to capture that moment of impact in detail - and have learned that these speeds are so intense, the impact actually partially melts the surface.

This was "unforeseen," based on previous research on erosion, the scientists said.

High-speed microscopic particles can actually be pretty useful, and the way they erode surfaces isn't all bad. Sandblasting is one such application, or applying coatings.

But they can be dangerous, too - like micrometeorites bombarding the ISS, for example, or particles carried by strong winds hitting wind turbines.

"We want to understand the mechanisms and exact conditions when these erosion processes can happen," explained engineer Mostafa Hassani-Gangaraj of MIT.

So he and his team came up with a series of experiments to find out, using a microparticle impact testbed developed at MIT. With a framerate of up to 100 million FPS, the testbed can record at the incredibly high speeds required.

They then set up a tin surface, and used a laser to heat up another piece of tin. This evaporates the substrate surface, and ejects and accelerates microscopic particles of tin in the process. This resulted in tin particles about 10 micrometres in diameter - about 0.01 millimetres - hitting the tin surface at speeds of up to a kilometre per second (2,237 miles per hour).

They also used lasers to illuminate these impacts for a clear view of what was happening.

This allowed them to see, for the first time, the mechanism that produces the damage, rather than relying on examination of the surface after the impact.

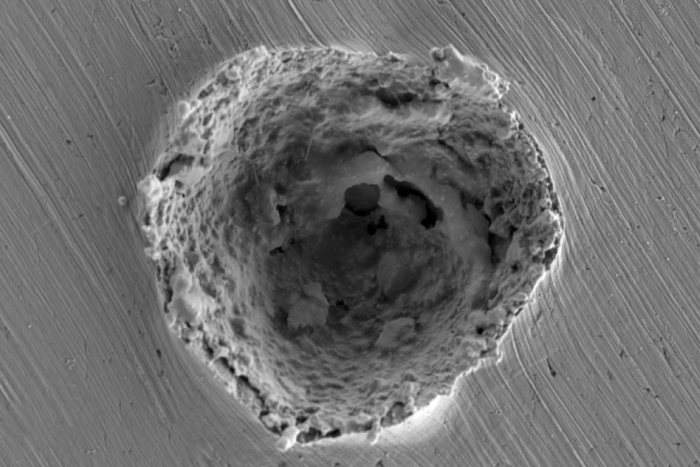

And there, in the video, you can clearly see molten material splashing away from the impact site.

Scanning electron micrograph of one of the impacts from a 10μm particle at 1kps. (Hassani-Gangaraj et al.)

Scanning electron micrograph of one of the impacts from a 10μm particle at 1kps. (Hassani-Gangaraj et al.)

This information is actually incredibly valuable. It can help improve, for instance, those industrial processes that use high-speed microparticles, where the accepted wisdom, according to the researchers, is that higher speeds achieve better results.

These results show that this is not always the case - crank it up too high and you can melt things without intending to do so.

This can also help us understand how microparticles can damage turbines, and spacecraft, and oil pipelines. And what about the poor robots on Mars, weathering those insane dust storms. Equipped with this new knowledge, engineers could develop more erosion-resistant materials, both for space and terrestrial applications.

Obviously there's a bit more research to be done. The team only used tin, and at a direct impact angle. There will probably be slightly different effects for different materials - with different levels of hardness or toughness, and different melting points (tin's is pretty low), as well as different impact angles.

But this first step, in demonstrating that the testbed and experimental setup can be used to capture and analyse that moment of impact, is highly impressive.

"We can extend this to every situation where erosion is important," said MIT engineer David Veysset.

The team's research has been published in the journal Nature Communications.