Villages on the Moon built by huge 3D printers and inhabited for months at a time by teams of astronauts could be a reality in the next decade or so, a recent conference of 200 scientists, engineers, and industry experts has concluded.

Construction of this manned lunar base could begin in as little as five years, the European Space Agency (ESA) announced at their International Symposium on Moon 2020-2030 in the Netherlands last month, suggesting that a new Moon village could provide a potential springboard for future missions to Mars.

"The ESA space-exploration strategy sets the Moon as a priority destination for humans on the way to Mars," NASA's Kathy Laurini told Leonard David at Space.com. "The timing is right to get started on the capabilities which allow Europe to meet its exploration objectives and ensure it remains a strong partner as humans begin to explore the Solar System."

NASA in particular has a vested interest in seeing this happen, as the Moon has been designated the most strategic pitstop for a manned mission to Mars, with MIT scientists calculating last month that astronauts could launch from Earth with up to 68 percent less mass if they collected most of their heavy liquid fuel from a Moon base on the way.

Add that to the fact that NexGen Space LLC, a consultant company for NASA, recently estimated that a lunar refuelling station would "reduce the cost to NASA of sending humans to Mars by as much as $US10 billion per year", and a Moon village is starting to look pretty inevitable.

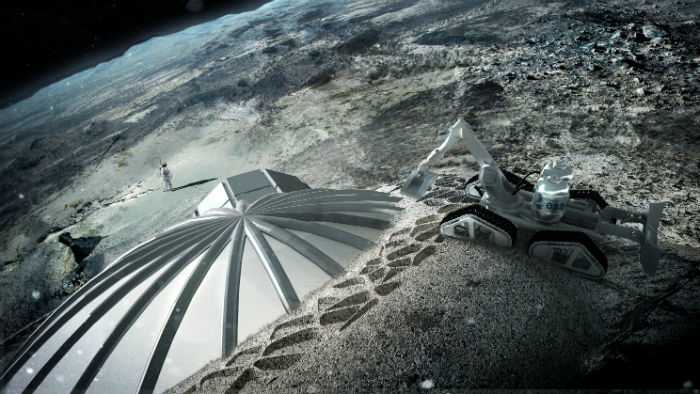

The plan outlined by the ESA is that, starting from the early 2020s, robots will be sent to the Moon to begin constructing various facilities, followed a few years later by the first inhabitants.

Back in 2013, the ESA teamed up with building companies to start testing out various Moon base-building technologies, and determined that local materials would be the best for constructing buildings and other structures, which means no need for transporting resources from Earth at an astronomical cost.

ESA/Foster + Partners

ESA/Foster + Partners

"First, we needed to mix the simulated lunar material with magnesium oxide. This turns it into 'paper' we can print with," Enrico Dini, founder of UK manufacturing company, Monolite, said at the time.

"Then for our structural 'ink', we apply a binding salt which converts material to a stone-like solid. Our current printer builds at a rate of around 2 metres per hour, while our next-generation design should attain 3.5 metres per hour, completing an entire building in a week."

Architectural firm Foster + Partners came up with a weight-bearing 'catenary' dome design, which features a cellular structured wall to shield residents against micrometeoroids and space radiation, and a hollow closed-cell structure that would give the building a good strength-to-weight ratio.

Once we're there, scientists argued, we could figure out if the resources on the Moon are as valuable as we think they are.

"We keep talking about lunar resources, but we still need to demonstrate they can be used … [that] they are, in fact, reserves," engineer Clive Neal from the University of Notre Dame told Space.com. "So ground truth verification of deposit size, composition, form and homogeneity requires a coordinated prospecting program. A successful program would then clearly demonstrate that lunar resources can enable solar system exploration."

Whether the Moon village becomes a reality in the next decade or so, NASA is determined to get its astronauts orbiting around it for months at a time, announcing last month that it's "going to get out of ISS as quickly as we can" to set up shop near the Moon instead.

There they will be days, instead of hours, away from Earth, and far from its protective geomagnetic shield, which will give astronauts a better idea of what they would have to endure physically and psychologically on a manned mission to Mars.

One thing's for sure - we're in for some exciting times ahead.

ESA/Foster + Partners

ESA/Foster + Partners