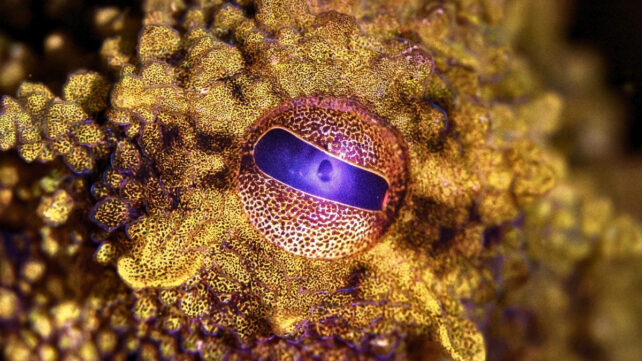

Octopuses and other cephalopods are masters of camouflage, thanks largely to color-changing skin that can help them seemingly vanish into the background. Now, researchers report a big step towards being able to recreate their superpower.

A team led by UC San Diego was able to mass-produce a key pigment, xanthommatin, that occurs in the psychedelic skin of many cephalopods. Until now, xanthommatin has proven impractical to collect from animals or make in a lab.

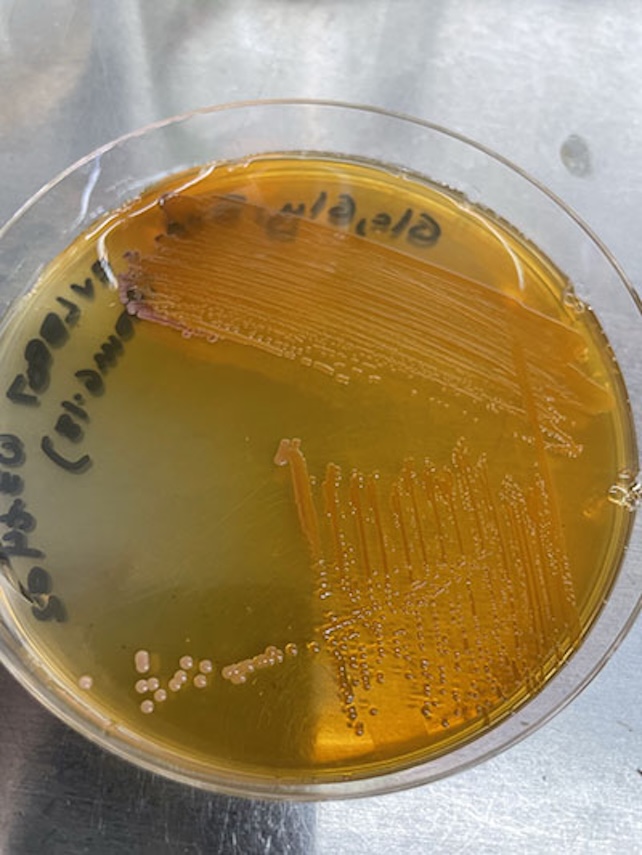

The researchers technically didn't make the pigment. They bioengineered bacteria to make it, coaxing microbes to not only produce this rare substance, but to do so with unprecedented efficiency, yielding up to 1,000 times more xanthommatin than previous methods.

Related: Squids' Amazing Color Shifting Could Be Key to Hyper-Efficient Solar Tech

Easier access to xanthommatin could aid efforts to study cephalopod camouflage, potentially shedding new light on this wonder of nature – and offering clues to help us mimic it.

Beyond boosting humanity's quest for octopus powers, the new study also has implications for our growing grasp of microbial manufacturing. If bacteria can be similarly persuaded to produce other chemicals, it could lead to major upgrades from current industrial practices.

"We've developed a new technique that has sped up our capabilities to make a material, in this case xanthommatin, in a bacterium for the first time," says senior author Bradley Moore, a marine chemist with Scripps Oceanography and the University of California San Diego.

"This natural pigment is what gives an octopus or a squid its ability to camouflage – a fantastic superpower – and our achievement to advance production of this material is just the tip of the iceberg," Moore says.

To get high yields from reluctant bacteria, they used a new method they call "growth-coupled biosynthesis," which incentivized bacteria to make lots of xanthommatin by connecting their survival to pigment production.

"We needed a whole new approach to address this problem," says lead author Leah Bushin, who led the study in the Moore Lab at Scripps Oceanography.

"Essentially, we came up with a way to trick the bacteria into making more of the material that we needed."

Bacteria are practical organisms, and they don't like to waste their meager resources making products that aren't strictly necessary for their survival.

So, Bushin and her colleagues made the bacteria an offer they couldn't refuse. They genetically engineered "sick" cells, which could only grow if they continued producing two compounds: xanthommatin and formic acid.

The latter served as fuel, and since a bacterium made one formic acid molecule for each new pigment molecule, it had enough fuel to grow – as long as it made pigment. This feedback loop then sustained intensive pigment production.

"We made it such that activity through this pathway, of making the compound of interest, is absolutely essential for life," Bushin says. "If the organism doesn't make xanthommatin, it won't grow."

The technique yielded up to 3 grams of pigment per liter of the medium. That doesn't sound like much, but it's far higher than the 5 milligrams per liter you'd get from other methods, the team says.

Once conditions were in place, the team didn't have to wait long for results.

"It was one of my best days in the lab," Bushin says. "I'd set up the experiment and left it overnight. When I came in the next morning and realized it worked and it was producing a lot of pigment, I was thrilled. Moments like that are why I do science."

On top of the feedback loop driving this strategy, the researchers optimized their creations with adaptive laboratory evolution, and used bioinformatics tools to improve efficiency and empower the microbes to synthesize pigment from a single nutrient source, like glucose.

The results hint at dramatic potential for this concept, says co-author Adam Feist, bioengineer at UC San Diego.

"This project gives a glimpse into a future where biology enables the sustainable production of valuable compounds and materials through advanced automation, data integration, and computationally driven design," Feist says.

"Here, we show how we can accelerate innovation in biomanufacturing by bringing together engineers, biologists, and chemists using some of the most advanced strain-engineering techniques to develop and optimize a novel product in a relatively short time."

The study was published in Nature Biotechnology.