In addition to everything else that winemakers have to consider in the production of a perfect bottle is the smell of the drink: In certain types of winemaking processes, that smell can end up being rather undesirable.

Aromas that you might describe as "rotten eggs", "rubber" and "canned corn" are often termed as 'reductive' and are created by volatile sulfur compounds (VSCs) in the liquid. These compounds can affect both red and white wines, both large-scale and small-scale operations, and are a costly headache for the industry.

Now researchers from the Australian Wine Research Institute and Flinders University in Australia have come up with a novel solution to the problem: gold nanoparticles that can remove a lot of sulfur quickly and in an eco-friendly way.

"Volatile sulfur compounds, such as hydrogen sulfide, methanethiol, and ethanethiol, are associated with 'reductive' aromas in wine and contribute to approximately 30 percent of all wine faults," write the researchers in their published paper.

"These compounds can have a significant impact on wine aroma and perceived quality, and subsequently, consumer preference."

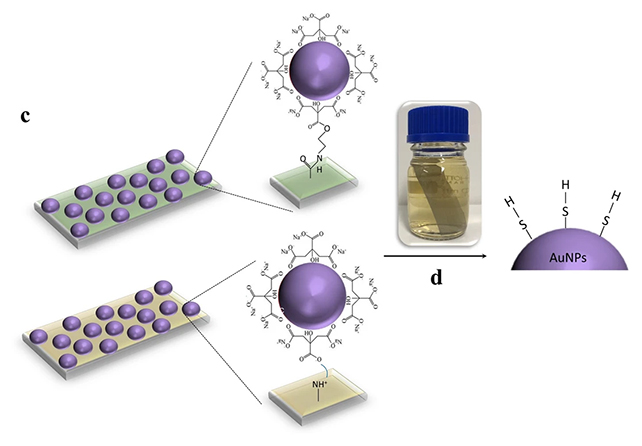

Researchers chose gold nanoparticles because of the way that gold binds with certain sulfur molecules. The team applied a specially developed thin plasma polymer coating to the surface of a neutral substrate, before fixing the nanoparticles to it.

In the lab, small strips carrying the nanoparticle-enhanced coating were tested on small samples of red and white wine high in VSCs. The researchers found that after 24 hours of exposure, up to 45 percent of the free hydrogen sulfide in the wines had been removed, together with other unwanted VSCs including methanethiol.

This surface coating is pretty versatile, too. It can be used on equipment all the way through the winemaking process, from filtration devices (for removing solids) and decanters, to the packaging materials that the wine is put in.

"A key benefit of the new approach is that it is easily deployable and retrievable," says Agnieszka Mierczynska-Vasilev, a principal research scientist at the Australian Wine Research Institute.

"Essentially there's a one-step process where the smart surface is added directly to the wine and then removed after a certain time period."

It's going to take some time to get this process out of the laboratory and into commercial processes of course, but these early results are very promising in improving wine quality (and without resorting to any psychological tricks).

The new method is more effective at limiting VSCs than the current approach of adding copper sulfate, which comes with its own problems: It can introduce other unwanted flavors, and its use is regulated for health reasons.

What's more, the copper sulfate option is a multi-step process, whereas the gold nanoparticle material is more straightforward. It's applied to the wine for a certain time period and then removed.

"Adopting a sustainable, non-toxic alternative to copper fining would therefore have the potential to provide beneficial environmental and economic impacts," write the researchers.

The research has been published in npj Science of Food.