Scientists have developed a new prototype battery inspired by the anatomy of the human intestine, and the biologically informed approach could pave the way for much more powerful energy sources for our digital devices.

The prototype – which offers up to five times the energy density of the lithium-ion batteries we use in smartphones and laptops – uses a lithium-sulphur cell instead, and its intestine-mimicking design could finally make these energy-dense batteries long-lasting enough for commercial use.

The research, led by a team from the University of Cambridge in the UK, overcomes one of the major drawbacks of lithium-sulphur batteries, which is that they degrade much faster than lithium-ion cells, despite their superior energy density.

When a lithium-sulphur battery discharges, sulphur in the cathode (the battery's positive electrode) absorbs lithium from the anode (negative electrode). This interaction causes the sulphur molecules to transform into chain-like structures called poly-sulphides.

After the battery goes through numerous charge-discharge cycles, the reaction starts to stress the cathode, leading to bits of the poly-sulphides breaking off and entering the battery's electrolyte, which joins the two electrodes.

When this happens, the battery starts to degrade, as it loses its active material that stores the energy.

And that's where the gut inspiration comes in.

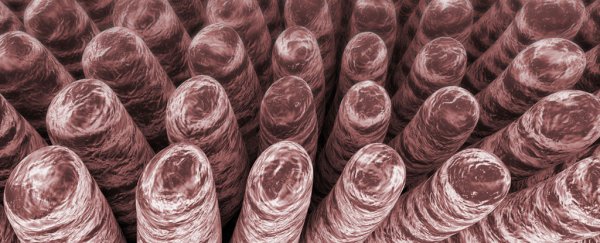

In the human body, our small intestines are lined with millions of tiny, finger-like protrusions called villi. These protrusions extend internally from the intestinal walls and help us to absorb nutrients during digestion.

They do this by dramatically increasing the surface area of our intestinal lining, by up to about 30 times.

Using the same kind of principle, the team developed a lightweight nanostructure material that resembles villi – so when the poly-sulphides break off, they get caught by the protrusions and not lost in the electrolyte.

The villi-like structure is a layer made up of tiny zinc oxide wires, which covers the surface of the battery's electrodes. These wires effectively trap the battery's active material when it becomes loose, keeping it electrochemically accessible to the cathode and anode, and preventing the battery from degrading.

"It's a tiny thing, this layer, but it's important," says material scientist Paul Coxon from the University of Cambridge. "This gets us a long way through the bottleneck which is preventing the development of better batteries."

While lithium-sulphur batteries have been in development for several years, it's been difficult for anybody to commercialise the technology due to the way the cells lose capacity when sulphur dissolves into the electrolyte.

But thanks to the villi-like scaffold, that might not be a problem going forward.

"This is the first time a chemically functional layer with a well-organised nano-architecture has been proposed to trap and reuse the dissolved active materials during battery charging and discharging," says one of the researchers, Teng Zhao.

"By taking our inspiration from the natural world, we were able to come up with a solution that we hope will accelerate the development of next-generation batteries."

In testing, the nanostructure saw that the prototype only lost about 0.05 percent of its energy capacity per cycle after 200 charging cycles, making it almost as stable as lithium-ion – which ranges between 0.025 to 0.048 percent average capacity loss per cycle.

The researchers acknowledge that their prototype is only a proof of concept for now, meaning it might be years before we see lithium-sulphur batteries in our smartphones, cameras, and handheld consoles.

But now that we know how to stabilise this energy platform, it means we're a big step closer to more powerful batteries, and getting past the limitations of lithium-ion.

"This is a way of getting around one of those awkward little problems that affects all of us," says Coxon.

"We're all tied in to our electronic devices – ultimately, we're just trying to make those devices work better, hopefully making our lives a little bit nicer."

The findings are reported in Advanced Functional Materials.