Scientists have created an inexpensive material that removes a highly toxic industrial pollutant from water.

The filtration material is made by turning a naturally occurring sugar molecule into a polymer and it performs much better than our current filtration technology at dealing with one big contamination problem.

Industrial pollutants cause major issues for communities near industrial sites. In the US, Hoosick Falls, New York, and Bennington, Vermont, declared states of emergency because of chemical contamination of drinking water in 2016.

The main culprit? Perfluorooctanoic acid – which can be shortened to the acronym PFOA.

PFOA is a molecule that has been used historically in the production of our non-stick friend, TEFLON, and as a water and oil repellent for carpets, food wrapping and even dental floss.

But there's a serious price to pay for our stain free and non-stick existence.

PFOA is toxic to living things and, once released into the environment, it will never break down. This means removing PFOA from the contaminated waterways is the only course of action we have to improve the water quality.

Scientists have created a new polymer material constructed from a simple sugar molecule, beta-cyclodextrin. The material is ten times more efficient at removing PFOA from water than commonly used filtration materials such as activated carbon (the same stuff now used in fart absorbing underwear).

"Our material fully extracts the pollutant out of water. The polymer contains sites that bind PFOA strongly, which strips this pollutant out of water even when present at extremely low concentrations" said lead researcher William Dichtel from Northwestern University, Illinois.

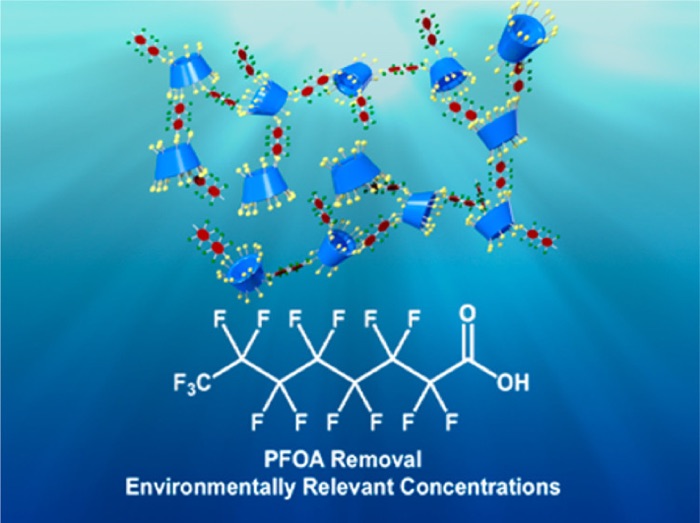

Beta-cyclodextrin is a naturally occurring bio-renewable sugar molecule derived from cornstarch. The cyclodextrin is transformed into a polymer by connecting the molecules together with another molecule – known as cross linking. Perfecting the ratio of beta-cyclodextrin to cross-linker was the key to maximising the filtration efficiency.

As the name suggests, cyclodextrins are made up of sugar molecules bound together in a ring. The ring-like nature of beta-cyclodextrin creates a molecular bucket that's the perfect size for capturing and holding on to the PFOA molecules.

Credit: American Chemical Society

Credit: American Chemical Society

Targeting for other pollutants can be programmed into the material by changing the cyclodextrin for one with bigger or smaller cavities.

"Our findings demonstrate the selectivity of this type of polymer can be tailored to target pollutants of interest, in this case PFOA," said Dichtel.

Even very small amounts of the beta-cyclodextrin polymer can reduce the levels of PFOA to below the environmental protection agency's advised limit of 70 parts per trillion, which is equal to one teaspoon of PFOA in 14 Olympic-sized swimming pools.

In the study, the scientists were able to take contaminated water with PFOA from a concentration of one milligram per litre (similar to that of contaminated water resources) to concentrations as low as 10 nanograms per litre – far below the Environmental Protection Agency's advised limits.

The best performing polymers made could remove up to 95 percent of the PFOA within 13.5 hours.

To make the polymer even better, it was able to be used multiple times by simply washing it with methanol at room temperature. Importantly, it was also resilient to humic acid, a component of natural organic matter which is commonly found in waterways and stops activated carbon filters from working.

The scientists are hoping to turn this material into a commercial product very soon and have founded a start-up to manufacture and distribute the material.

The findings were published in the Journal of the American Chemical Society.