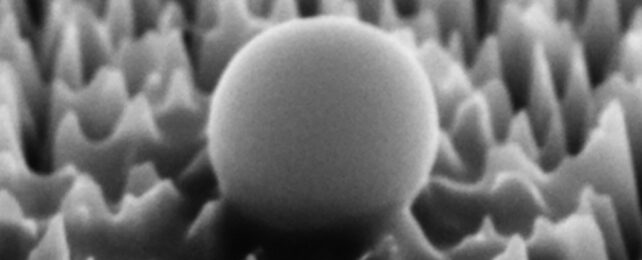

A newly developed silicon material covered with tiny nanospikes is capable of taking out 96 percent of the virus particles unfortunate enough to touch its surface in tests. It could find a use in hospitals, science labs, and anywhere surfaces need to be as sterile as possible.

The nanospikes literally skewer virus particles as they make contact, according to the team behind the study, led by researchers from the Royal Melbourne Institute of Technology (RMIT) University in Australia.

This action breaks the viruses apart or damages them enough to stop them from reproducing. It's somewhat like puncturing a balloon, with almost all viral activity on the surface wiped out in six hours.

The team says the 96 percent hit rate would be enough to protect most healthy individuals from an array of pathogens communicable through surface contact.

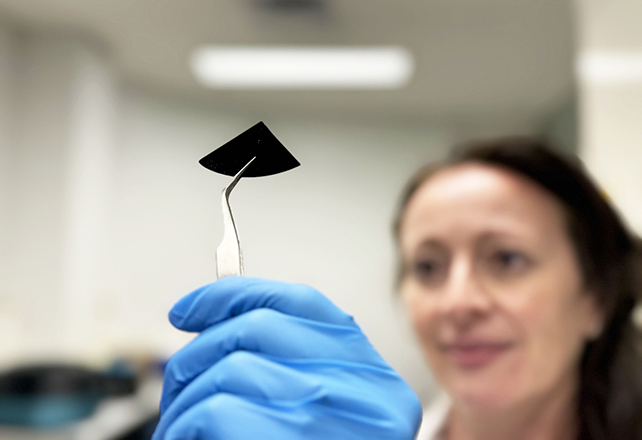

"Our virus-killing surface looks like a flat black mirror to the naked eye but actually has tiny spikes designed specifically to kill viruses," says RMIT molecular biologist Natalie Borg.

"This material can be incorporated into commonly touched devices and surfaces to prevent viral spread and reduce the use of disinfectants."

The approach was inspired by nature: insects, including dragonflies and cicadas, have nanoscale spikes on their wings, which can destroy bacteria and fungi. In the case of viruses, though, the particles are much smaller, so the spikes have to be, too.

Using a technique where streams of ions were used to cut away parts of a thin silicon wafer, the researchers created a surface with spikes just 290 nanometers high and tips just 2 nanometers thick (30,000 times thinner than a human hair).

The bug-destroying properties of the material were then tested in both practical and theoretical terms, using four different types of human parainfluenza virus (hPIV-3) – responsible for illnesses including bronchitis, pneumonia and croup. It's the most virulent of the human parainfluenza viruses.

"Notably, our study provides valuable insights into the design and optimization of antiviral surfaces with a particular emphasis on the crucial role played by sharp nanofeatures in maximizing their effectiveness," write the researchers in their published paper.

While this is only at the lab stage, if this surface material can be scaled up and applied in healthcare environments, it could make a huge difference: hPIVs are behind a third of acute respiratory diseases, with children particularly at risk.

We know that hospitals – which often contain people with poor immune responses in close proximity – are places where viruses can quickly spread if left unchecked. Next, the researchers want to try experiments with different configurations of the material, and with different virus types.

"Implementing this cutting-edge technology in high-risk environments like laboratories or healthcare facilities, where exposure to hazardous biological materials is a concern, could significantly bolster containment measures against infectious diseases," says RMIT applied physicist Samson Mah.

The research has been published in ACS Nano.