The ancient Romans might have taught us a thing or two about manufacturing sustainable concrete that lasts for thousands of years.

A new study has rigorously analyzed the raw materials and energy demands of their ancient recipe, revealing some useful ways to improve modern cement.

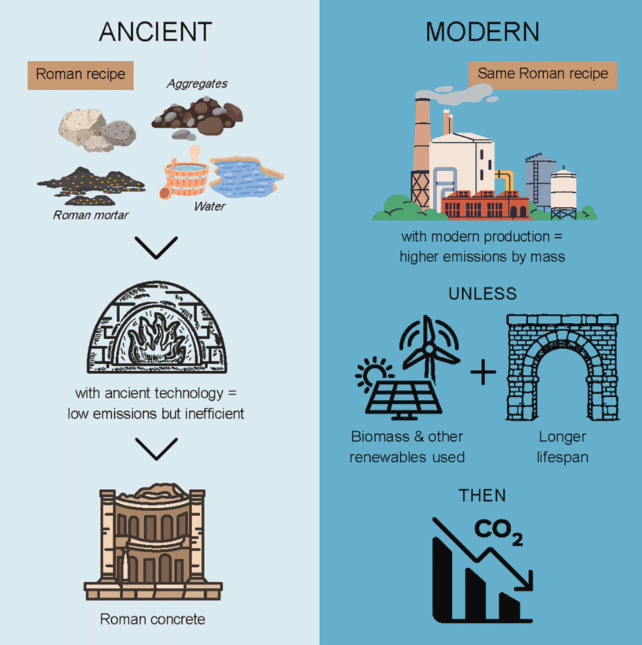

Surprisingly, researchers found that producing Roman mortar and concrete requires more water and more greenhouse gas emissions than Portland cement – the most common type of cement used in concrete today.

But while the initial energy costs may be steeper, Roman concrete formulations could ultimately prove more sustainable in the long run. That's because they may not need to be replaced or repaired as often.

Related: Scientists Developed a Kind of 'Living Concrete' That Heals Its Own Cracks

According to an international team of environmental engineers, Roman concrete mixtures would need to outlive modern formulations by at least 41 percent to achieve the same cumulative emissions for buildings.

For shorter-lived structures, like streets and highways, Roman concrete would need to last at least 29 percent longer.

"When we take concrete's service life into consideration, that's when we start seeing benefits," says lead author and engineer Daniela Martinez of the University of the North in Columbia.

"There's a lot of lessons that we can draw from the Romans. If we can incorporate their strategies with our modern innovative ideas, we can create a more sustainable built environment."

It's hard to compare the longevity of Roman concrete to modern concrete, because today, many concrete buildings and structures are reinforced with steel.

As steel rusts it expands, forcing any surrounding concrete to crack and degrade in as little as a decade. By comparison, ancient Roman concrete is capable of 'self-healing'. This means that when cracks appear in the cement, they are naturally glued back together when water leaks in.

That's part of the reason ancient Roman seawalls have endured for millennia, despite constant battering by waves and corrosive saltwater.

Whether or not modern concrete is capable of the same is unclear.

"Corrosion of steel reinforcement is the main cause of concrete deterioration, so comparisons should be made with great care," explains author and engineer Paulo Monteiro of the University of California, Berkeley.

Martinez and her team acknowledge that longer-lasting cement structures "can only partially offset increased demand for new material," but Roman manufacturing methods may also hold other environmental perks.

Both Portland cement and Roman cement are made using the same main ingredient. When limestone is heated, it produces a highly reactive caustic powder called quicklime. Combined with water, this powder forms a powerful mortar.

Concrete formulations in the ancient Roman Empire varied quite a lot, but they generally mixed this mortar with locally available volcanic rocks, rather than the gypsum used in modern concrete.

Roman concrete also produces far fewer dangerous air pollutants, possibly because the limestone is burned using oak and fir wood, not fossil fuels.

According to recent models, using Roman cement techniques could reduce nitrogen oxide and sulfur oxide emissions by up to 98 percent compared to modern methods.

"Using biomass and other alternative fuels to fire kilns may prove more effective in decarbonizing modern cement production than implementing Roman concrete formulations," says Martinez.

Today, concrete is the second most widely used material in the world, after water. Its production accounts for roughly 8 percent of global anthropogenic carbon emissions, which is about a quarter of all industry carbon emissions.

According to Arizona State University materials scientist Narayanan Neithalath, if cement manufacturing were ranked as an individual country, it would be the third-largest carbon dioxide emitter in the world after China and the United States.

"If we stand a reasonable chance of staying below the two degrees Celsius warming target set by the Paris Agreement, cement-related emissions will have to fall by more than 20 percent in the coming decade," Neithalath explained in 2023.

Studying ancient Roman concrete could help us achieve those pressing climate goals.

The study was published in iScience.