Nicknamed ' graphene's cousin', silicene - a form of silicon made from a two-dimensional lattice structure of silicon atoms - has been touted as a super-material in its own right, and now, computer engineers in the US have managed to make a transistor out of this notoriously tricky material.

This feat, achieved by computer engineer Deji Akinwande from the University of Texas and his team, has proven for the first time that silicene can be stabilised and sandwiched into a functioning transistor device - something no one thought would even be possible.

Scientists have theorised about the existence of silicene for over two decades, but it wasn't until 2010 that anyone was actually able to make it. This was an exciting development, because like graphene, it's got some amazing electrical properties that could revolutionise computing technology - for example, it allows electrons to zoom through it as if they had no mass, and this unencumbered movement means the potential for extraordinarily speedy circuits running through our computer chips.

But there's a crucial difference between the two - graphene might be the most conductive substance on Earth (that we know of), but it lacks what's known as 'band gap' - the minimum amount of energy required to excite an electron out of a bound state and into a free state, which allows it to participate in conduction. "Band gaps enable semiconductor devices to switch on and off and to perform 'logic' operations on bits," says Mark Peplow at Nature Magazine, which means graphene is pretty much out when it comes to making computer chips.

"For logic applications, graphene is hopeless," Guy Le Lay, a materials scientist at Aix-Marseille University in France, told Peplow. Le Lay wasn't involved in this research, but has worked with silicene in the past, as part of one of the few research teams in the world to create a layer of the stuff from scratch.

And another bonus for silicene over graphene - as Katherine Bourzac from MIT's Technology Review puts it, is that "it's made from the stuff Silicon Valley was built on". This means it'll be a whole lot easier for computer chip manufacturers to work with, because they're more used to working with silicon-based materials than carbon-based graphene.

"If we can get good properties out of it, it can be translated immediately by the semiconductor industry," Akinwande told her.

While the performance of the transistor isn't great, and the whole thing dies in just a few minutes, it's the proof of concept that yes, silicene can be used to construct a transistor, that's gotten people excited. "Nobody could have expected that in such a short time, something that didn't exist could make a transistor," Le Lay told Nature Magazine.

The reason for all the skepticism surrounding silicene is that it doesn't occur naturally - unlike graphene - and the process to make it is so complex, only a handful of labs around the world have managed to produce a simple sliver of the stuff, let alone using that sliver to build an entire, functioning transistor out of it.

Alexander Hellemans explains the difference between the two at IEEE Spectrum:

"Geim and Novoselev had isolated graphene in an embarrassingly simple manner: They peeled it off graphite with Scotch tape. The creation of a silicene layer was much more difficult. 'There is no equivalent to graphite where you could simply peel it off, and that was the problem,' says Patrick Vogt, a physicist at the Technical University of Berlin. He led a team of researchers from France and Italy, who synthesised and investigated the properties of single layers of silicene [in 2012]."

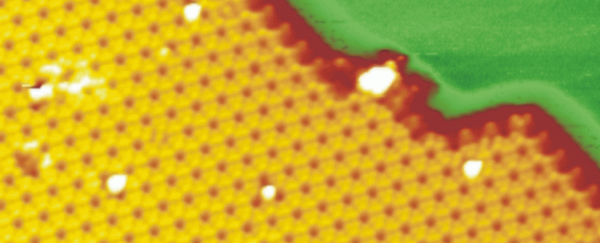

Silicene is made by producing a hot vapour of silicon atoms, and letting them condense down into a solid block inside a vacuum chamber. And that's the easy part. Silicene is so unstable, that just exposing it to the air will likely see it crumble, so how do you layer it a transistor?

Peplow describes at Nature Magazine that Akinwande's team managed to 'protect' their silicene layer from the cruel air around it by layering it on a thin strip of silver, and gently placing a 5-nanometre-thick layer of alumina on top. This "silicene sandwich", as Peplow describes it, is then flipped upside down, so the silver is on top, and laid into an oxidised-silicon substrate. "Finally, they gently etched away some of the silver to leave two islands of metal as electrodes, with a strip of exposed silicene between them," says Peplow.

The team describes the process in the journal Nature Nanotechnology.

It's still way too early to know if silicene can live up to what people are hoping its practical applications will be, but as Lok Lew Yan Voon, the physicist who published some of the first theoretical work on silicene back in 2007, told Katherine Bourzac at Technology Review, "They managed to do what many people have been trying to do."

We're excited to see what comes next.

Sources: Nature Magazine, IEEE Spectrum, Technology Review