Scientists have developed a new type of self-assembling silver membrane that could be used to capture carbon dioxide (CO2) emissions before they have a chance to spread in the atmosphere.

Using a technique the team says has never been attempted before, the researchers seeded their gas separation membrane with only a tiny deposit of the valuable metal, leveraging the flow of CO2 itself to grow tiny silver crystals or dendrites on the membrane.

These dendrites would then dramatically increase the efficiency of the structure, allowing for large amounts of CO2 and oxygen to flow through without having to use as much of the precious metal as in previous methods.

"We didn't build the entire membrane from silver," explains carbon capture engineer Greg Mutch from Newcastle University in the UK.

"Instead, we added a small amount of silver and grew it within the membrane, adding the functionality we desired."

The process is an example of what's called carbon capture and storage (CCS, aka carbon sequestration), a vast range of approaches for filtering CO2 emissions, with the aim of preventing them from flowing into the atmosphere and contributing to anthropogenic global warming.

A diverse number of industrial CCS projects have been implemented around the world, some going back decades. But the field is still evolving, with advancements in the science and economics of carbon capture being made all the time.

One big restriction holding back the roll-out of some of the most promising-looking hypothetical CCS ideas is cost. While scientists have limitless brilliant ideas that they can successfully realise in the lab, figuring out how to practically and cost-effectively scale up such methods to industrial-size executions is another thing.

Silver provides another example of this tension. While everybody knows it's a precious metal, most of us wouldn't be aware it's also a highly effective material for use in certain CCS applications.

There are a few different ways that CO2 can be separated from other gases during carbon sequestration, with absorption, adsorption, and the use of gas separation membranes representing the main players.

Membranes in CCS act as a permeable barrier to let some gases diffuse through, while stopping others. Silver, when used in a class of membrane called 'dual-phase, molten-carbonate membranes', offers some of the strongest efficiencies seen in CO2 separation, the researchers say.

Of course, it's not a cheap material, which is problematic. But in their new study, Mutch's team figured out a way of extracting the benefits of using silver in the CO2 separation process, while not actually needing a whole lot of the element itself.

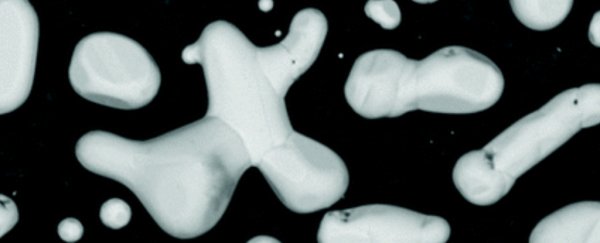

In experiments, the researchers used aluminium oxide pellets and tubes to form the basis of their membrane, only adding a little silver to the mix. As the membrane functioned, a network of silver dendrites began to grow upon the structure, stimulated by the permeation process taking place.

"Through permeation-driven non-equilibrium growth of Ag [silver] dendrites, from small quantities of added Ag, low-cost, low-flux membrane materials were transformed into low-cost, high-flux membranes," the researchers explain in their paper.

The team says their results achieved the highest flux of silver-supported molten-salt membranes to date, while reducing the volume of silver required by an order of magnitude.

"Most importantly, the performance of the membrane is at the level required to be competitive with existing carbon capture processes," Mutch says.

"In fact, it would likely reduce the size of the equipment required significantly and potentially lower operating costs."

Beyond the gains in cost-effectiveness if we want to use silver in CCS membranes, the team also suggests we could be looking at new ways to manufacture membranes here, by leveraging permeation mechanisms that haven't been fully explored before now.

"We propose that the non-equilibrium conditions of membrane permeation, routinely considered as deleterious for long-term stability, can instead be considered as favourable conditions to add advantageous functionality to membranes in situ," the researchers write.

The findings are reported in Energy & Environmental Science.