The traditional porcelain and ceramic toilet bowls could be on the way out, if a new 3D-printed design from scientists at the Huazhong University of Science and Technology in China catches on – with the key benefit being the ultra slippery surface.

Poop that clings to the toilet bowl is not only unpleasant for bathroom visitors and cleaners alike, it actually wastes a significant amount of water as more flushes are required to dislodge the stuff.

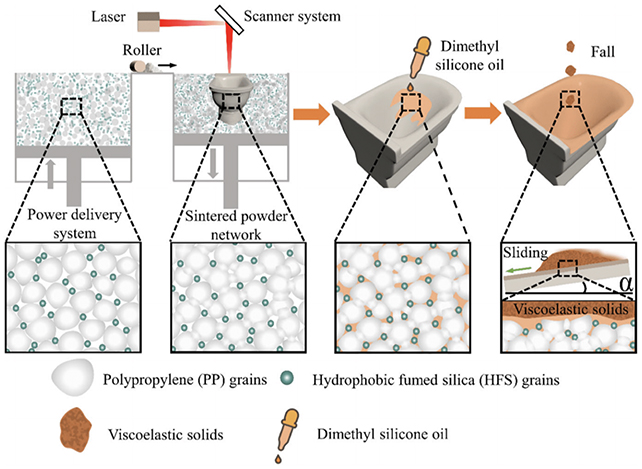

It was this problem that the scientists wanted to tackle by making a non-stick toilet bowl. They used a mixture of plastic and hydrophobic sand grains for their material, fused together with laser-based 3D printing techniques, in a design that was around a tenth the size of a standard toilet bowl.

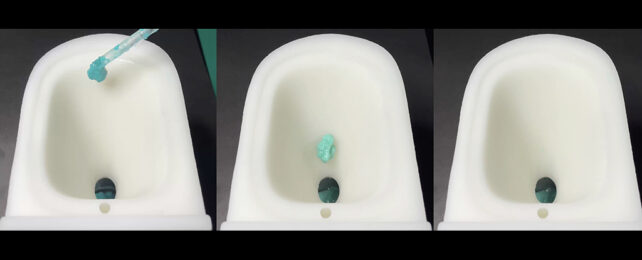

The abrasion-resistant super-slippery flush toilet, or ARSFT, was shown to repel synthetic feces, as well as multiple substances that the scientists tested. Nothing was able to get a grip on the surface, and everything slid straight down, much like the slippery pitcher plants that inspired the toilet design.

"The as-prepared ARSFT remains clean after contacting with various liquids such as milk, yogurt, highly sticky honey, and starch gel mixed congee, demonstrating excellent repellence to complex fluids," write the researchers in their published paper.

"Notably, even after being abraded to 1,000 cycles of abrasion using sandpaper, the ARSFT maintains its record-breaking super-slippery capability."

That durability is important: non-stick toilet surfaces have been developed before, but they tend to wear down with repeated flushing, so something that retains its slipperiness is a much better option for replacing conventional materials.

The 3D printing approach enabled the scientists to introduce some porousness to the surface, and add a silicon oil as a lubricant. Both of these innovations helped in the non-stick qualities of the small bowl.

What's more, the lubricant can be replenished to keep the bowl ultra slippy over time. Less water would be required for flushing and for cleaning, the scientists suggest, which would quickly add up across millions of toilets.

The flushing toilet has only been around properly for a couple of centuries, but we now use more than 141 billion liters of fresh water globally each day to flush toilets, which is nearly six times the daily water consumption of Africa.

Today, much of the world struggles to access safe, clean water, a problem that's only going to be exacerbated by climate change. Innovations such as this one promise to make a real difference – but the concept now needs to be developed and scaled up.

"The concept of the 3D-printed object with a superior abrasion-resistant slippery ability will improve the development of super-slippery materials and further save water consumption in the human society," write the researchers.

The research has been published in Advanced Engineering Materials.