Americans nibble their way through more than 3 million tons of chocolate each year, savoring the aromatic bitterness that only the seeds of the cacao plant can deliver.

To make the signature flavor palatable as a sweet treat, chocolate manufacturers combine a paste made from cacao seeds with sugar. Lots and lots of sugar – often enough to rival all the other ingredients combined, in fact.

Together with significant amounts of saturated fatty acids, provided by the addition of cocoa butter from the fruit, the few health benefits provided by the chocolate bean are swamped by ingredients that increase the risk of diabetes and cardiovascular disease.

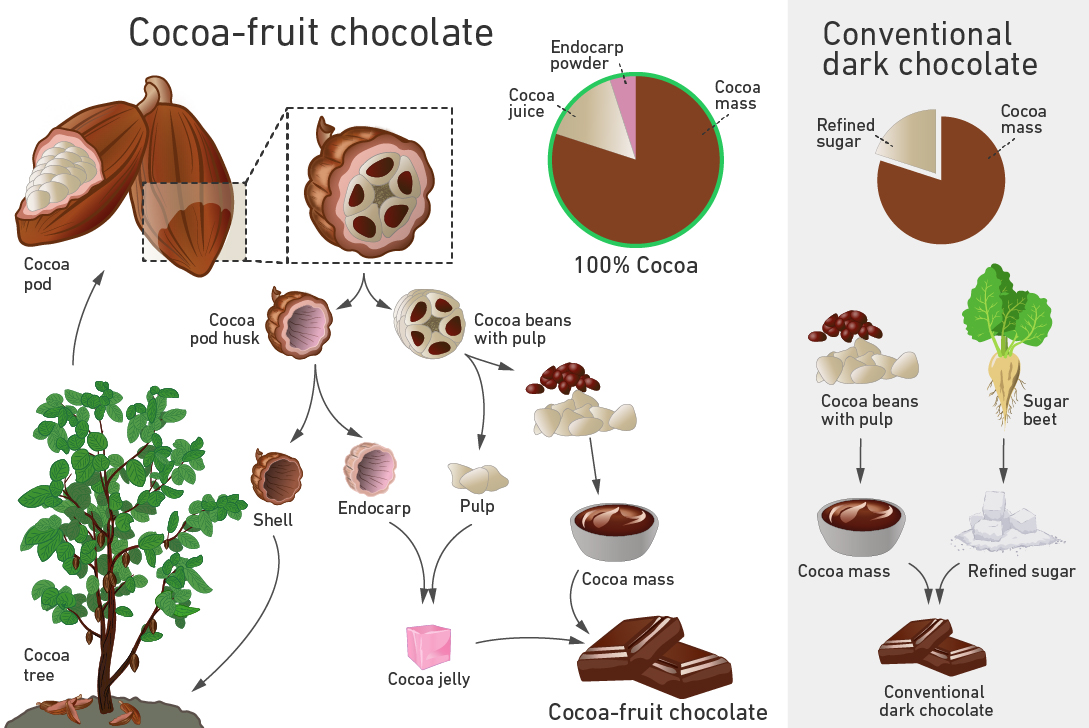

To address this stark imbalance, a team of researchers led by scientists from ETH Zürich in Switzerland has gone back to the basics and reinvented the chocolate recipe from the ground up. They've swapped out a portion of the refined sugar for a part of the cocoa fruit that's normally thrown away.

The fruit of the Theobroma cacao tree bears little resemblance to the delectable candy it's used to produce. Transforming the dozens of fleshy seeds inside each of the plant's fruit, or 'pods', requires an extensive process of fermentation, roasting, and grinding that turns the seeds and their pulpy outer covering into a fine paste.

Yet the pod from which the beans are plucked also contains a rich mix of materials that, according to the researchers, could be utilized for not just their sweetness, but their fiber as well.

"Fiber is valuable from a physiological perspective because it naturally regulates intestinal activity and prevents blood sugar levels from rising too rapidly when consuming chocolate," says the study's lead author Kim Mishra, a food technologist from ETH Zürich.

By separating and drying the fiber-rich inner wall – or endocarp – and combining it in powdered form with juice from the pulp that covers the cacao seeds, the researchers found they could make a sweet gel. Feasibly, this could be swapped for the heavily refined carbohydrates commonly added to chocolate recipes.

Tinkering with the temperatures and proportions of juice and endocarp powder eventually resulted in a perfect balance of flavor and mouth-feel.

Not only did the resulting chocolate contain a few more grams of fiber than conventional 100 gram blocks, it provided equivalent sweetness without the same load of sugar. Experiments based on trained volunteers showed that a product that was 20 percent 'whole fruit gel' was as sweet as chocolate that was around 5 to 10 percent powdered sugar.

By comparison, dark chocolate – often touted as a healthier option – tends to contain around 15 to 20 percent sugar.

As an added bonus, parts of the fruit normally discarded as organic waste could be retained and marketed, potentially providing cacao farmers with a much-needed additional source of revenue.

Transforming a novel product developed in a laboratory into a commercially-viable product requires the clearing of numerous hurdles, not least of which is the basic infrastructure.

"Although we've shown that our chocolate is attractive and has a comparable sensory experience to normal chocolate, the entire value creation chain will need to be adapted, starting with the cocoa farmers, who will require drying facilities," Mishra concedes.

Yet with the proof of the whole-fruit chocolate pudding now there in the eating, it's possible that there is enough incentive from a health-conscious market to bring this low-sugar, high-fiber alternative to supermarket shelves in the near future.

This research was published in Nature Foods.