The race is on to find practical substitutes for the petroleum-based plastics our societies have become so dependent on, and materials scientists from Rice University have a new lead.

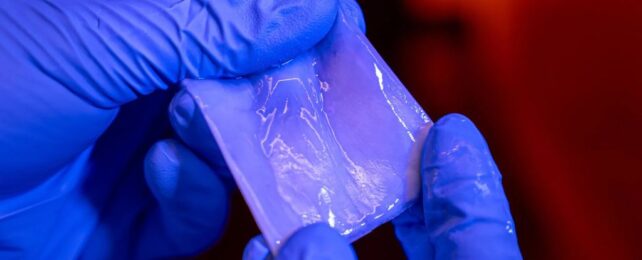

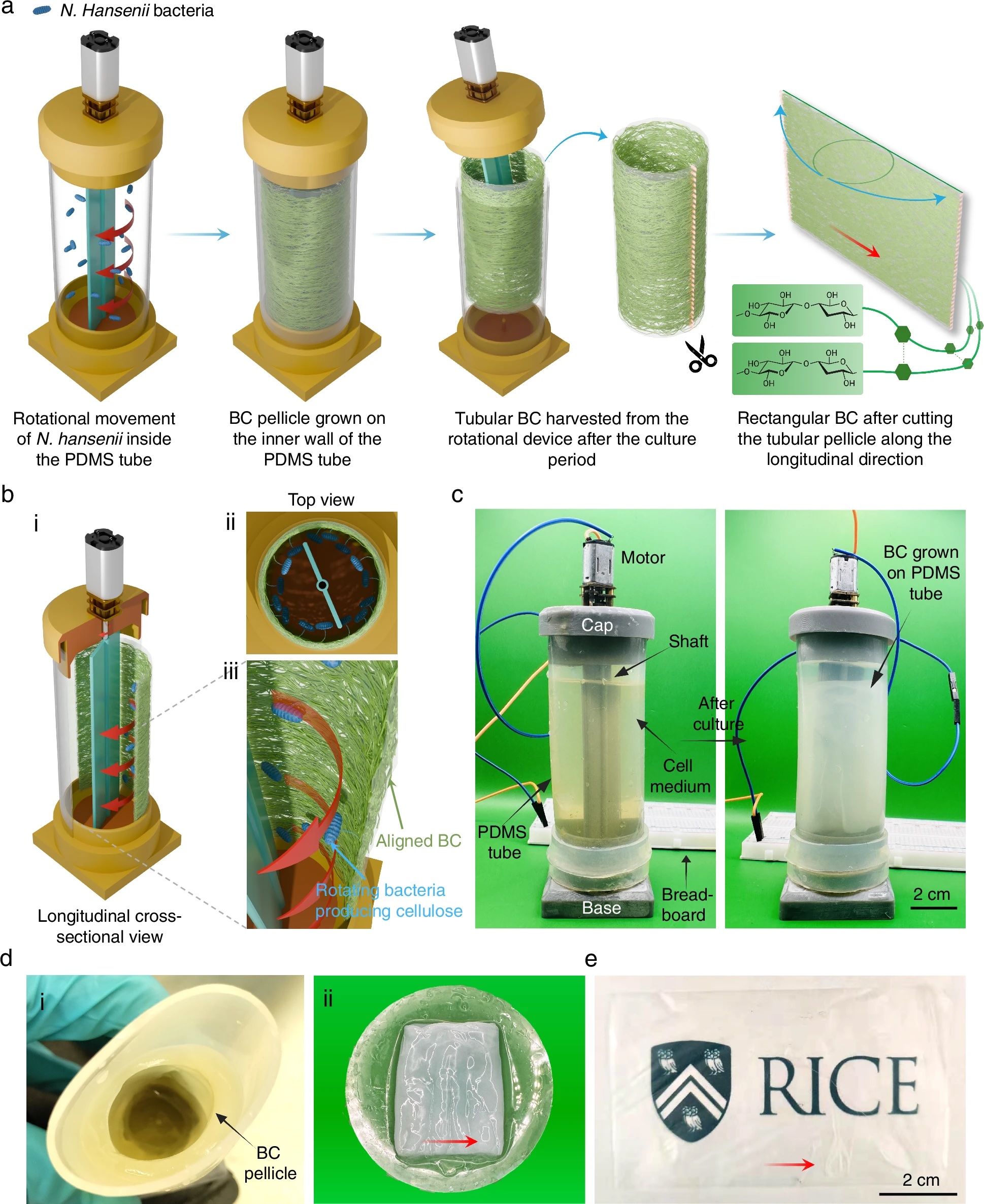

Their bacteria-produced biomaterial, BCBN (bacterial cellulose-hexagonal boron nitride), transforms what is naturally a random arrangement of bacterial cellulose fibers by rotating the microbes as they grow inside a bioreactor. This aligns the fibers, unlocking mechanical properties that rival some metals, glasses, and plastics.

Related: These Bacteria Can Transform CO2 in The Air Into a Useful Bioplastic

"Instead of having the bacteria move randomly, we instruct them to move in a specific direction, thus precisely aligning their cellulose production," says M.A.S.R. Saadi from Rice University.

"The method allows for the easy integration of various nanoscale additives directly into the bacterial cellulose, making it possible to customize material properties for specific applications."

By simply growing the cellulose fibers in a spinning chamber, the team produced flexible, transparent sheets with tensile strength up to 436 megapascals (about the same as low-carbon steel).

But when they added hexagonal boron nitride nanosheets to the nutrient solution that feeds the bacteria, the material acquired the ability to dissipate heat three times faster than regular bacterial cellulose. And its tensile strength was bumped up to 553 megapascals.

Research lead Muhammad Maksud Rahman has high hopes that this biodegradable material could replace plastic in a range of settings, including electronics, energy storage systems, and thermal management.

"We envision these strong, multifunctional and eco-friendly bacterial cellulose sheets becoming ubiquitous, replacing plastics in various industries and helping mitigate environmental damage," he says.

The research was published in Nature Communications.