If you're after a DIY project to tackle this weekend, what about making your own sonic tractor beam, and controlling objects through the power of sound waves?

Thanks to instructions put together by computer scientist Asier Marzo, you can do just that, as long as you're prepared to do a little bit of soldering, screwing, and sawing along the way.

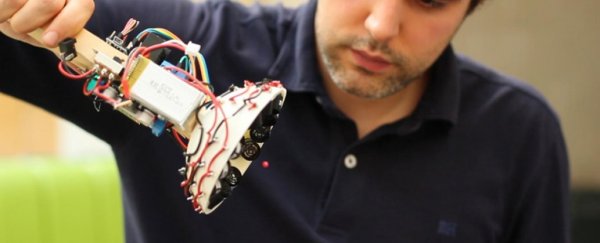

Marzo, a research assistant at the University of Bristol in the UK, was part of the team that invented the first working single-sided sonic tractor beam in 2015: a hand-held device able to move objects around in the air with no physical contact.

Now he's put together a simplified version that anyone can have a go at making. It's not expensive or difficult to do either, as long as you've got access to a 3D printer and some electronic components.

"Previously we developed a tractor beam, but it was very complicated and pricey because it required a phase array, which is a complex electronic system," says Marzo. "[Now we've] made a simple, static tractor beam that only requires a static piece of matter."

Moving objects imprecisely with sound isn't difficult, as you'll know if you've ever stood next to a very loud speaker: sound moves as a series of vibrations through air or some other physical medium.

But what makes a tractor beam special is it surrounds points of low acoustic pressure with high-intensity sound that's too high-pitched for the human ear to hear, trapping objects in a kind of sound cage.

Originally the stuff of science fiction, tractor beams are now being looked at for everything from 3D displays to new kinds of medical procedures – such as moving a kidney stone without making an incision.

Scientists have also tried moving objects with waves of light as well as sound, but for the time being the first real-life tractor beams are working at very small scales.

This new version of the sonic tractor beam uses the internal shape of a 3D-printed cone and its inner tubes to shape the sound waves. In fact, getting the device into a form simple enough for a 3D printer to cope with was one of the biggest challenges for the team.

"We needed to engineer the tubes very well to allow them to be 3D-printed with a normal 3D printer," Marzo says. "A normal 3D printer has a lot of limitations."

As well as access to a 3D printer, you're also going to need an Arduino Nano, a mesh of 30 transducers, and various bits of electronics to make this happen at home, but Marzo says you can source all the materials for less than £50 (about US$60).

The tweaks made to the design mean the homemade version isn't as versatile in terms of the type of sonic traps it creates, and it can only move objects up and down. Still it's a fantastic achievement to cut down the device's complexity and cost, and Marzo is keen to see more science projects opened up like this.

"We would like to continue this trend of making our research open access and releasing step-by-step videos of how to reproduce it," Marzo told Maarten Rikken at ResearchGate.

"We think there is great value in making science accessible so that everyone can take part in it."

There's a YouTube video, step-by-step instructions and an open access paper published in Applied Physics Letters if you want to have a go at this awesome project.