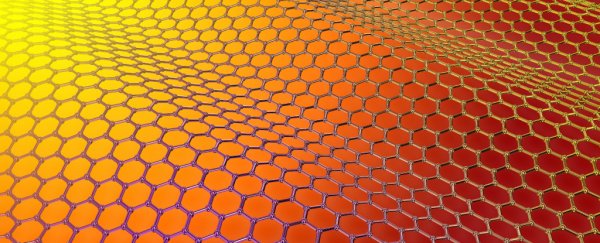

We all know graphene is great - it's super strong, it's only one atom thick, and it's flexible, light and able to conduct heat and electricity better than most other materials out there. In fact, the only reason it hasn't already revolutionised our energy, medical, and manufacturing industries is that it's remained prohibitively expensive.

But now researchers at the University of Glasgow in Scotland have found a way to produce large sheets of high-quality graphene 100 times more cheaply than previous methods.

Currently, the most common method of making graphene is known as chemical vapour deposition, which is where gaseous reactants are turned into a film of graphene on a special surface known as the substrate.

In the past, that substrate was always an expensive material such as platinum, nickel or titanium carbide. These materials are smooth, so they produce high-quality sheets of graphene, but they're also incredibly costly, which means it's not feasible for the graphene they make to be used in most industries.

Recently scientists have started using copper to reduce the price, but the metal still needs to be processed so it's definitely not cheap. Instead the University of Glasgow team decided to see if they could make graphene with copper foils, which are already being cheaply made in bulk to create common household lithium-ion batteries.

Without any processing, they found that these copper foils were smooth enough to make high-quality single-atom sheets of graphene.

Even more impressively, during testing, the graphene sheets displayed optical electrical properties that made them better suited for use in transistors than sheets that had been produced with an expensive substrate.

"The commercially-available copper we used in our process retails for around $1 per square metre, compared to around $115 for a similar amount of the copper currently used in graphene production," said lead researcher Ravinda Dahiya. "This more expensive form of copper often required preparation before it can be used, adding further to the cost of the process."

"Our process produces high-quality graphene at low cost, taking us one step closer to creating affordable new electronic devices with a wide range of applications, from the smart cities of the future to mobile healthcare," he added.

The new technique will make it feasible for scientists to finally start using graphene in new innovations such as high-tech filters and materials, as well as medical devices.

"Much of my own research is in the field of synthetic skin. Graphene could help provide an ultra-flexible, conductive surface which could provide people with prosthetics capable of providing sensation in a way that is impossible for even the most advanced prosthetics today," said Dahiya. "It's a very exciting discovery and we're keen to continue our research."

The research has been published in Scientific Reports.