Electronic wearables and sensors could one day be made from a material that toughens up as it gets hit or stretched, thanks to new research carried out by a team from the University of California, Merced.

This 'adaptive durability', as it's known, is an important characteristic in terms of the science of materials. It means protection against damage and resistance to stress, even in harsh environments.

The new material was actually inspired by the corn starch used in cooking, which can be stirred when water is added. Unlike wet sand, which has a consistent viscosity whether mixed or punched, cornstarch slurry acts like a liquid when stirred gently and like a solid when punched quickly.

When you squish cornstarch slowly, the tiny particles repel each other, making them act like a fluid. But if you hit the surface fast, they touch, causing friction and acting like a solid. This difference in behavior is due to the size of the particles.

The researchers wanted to see if they could get the same results from a polymer material.

To achieve this, the team started with conjugated polymers: polymers with special properties that help materials conduct electricity while staying relatively soft and supple. These materials can be made from all kinds of combinations of molecules.

In this case, they incorporated long molecules of poly(2-acrylamido-2-methylpropanesulfonic acid), short polyaniline molecules, and a highly efficient conductor – poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS). Don't worry if those names aren't familiar – all you really need to know is that the combination created a film that deformed or stretched out when it was hit by rapid impacts.

The faster the impacts, the tougher the material became. Adding 10 percent more PEDOT:PSS then improved both the adaptive durability and the conductivity of the material.

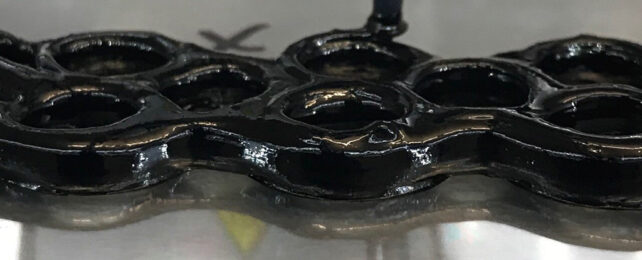

According to the researchers, their choice of two positively charged and two negatively charged polymers creates a material with super-small structures like miniature meatballs, in a tangled bowl of spaghetti. These 'meatballs' absorb the shock of the impacts, without breaking apart completely – keeping the material and its conductivity in place.

Further experiments suggest the addition of positively charged 1,3-propanediamine nanoparticles improve the toughness even further, slightly weakening the 'meatballs' (so the material could take bigger hits) while strengthening the 'spaghetti strings' around them (maintaining the integrity of the material).

This is all quite complex and technical, but there should be applications for the material outside of the lab, if it can be manufactured at scale. Smartwatch bands, wearable sensors, and health monitors – for cardiovascular health or glucose levels, for example – are all examples put forward by the research team.

Personalized electronic prosthetics are another potential use case, and something the researchers have already experimented with. Eventually, artificial limbs could be 3D printed from this versatile material.

It's another reminder of the potential for new materials to be discovered and existing materials to be refined, and how they might change our futures – from the devices we use to the clothes we wear.

"There are a number of potential applications, and we're excited to see where this new, unconventional property will take us," says materials scientist Yue Wang.

The research has been presented at the Spring 2024 meeting of the American Chemical Society.